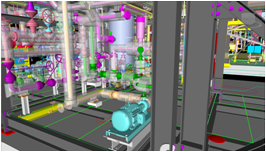

Piping Design

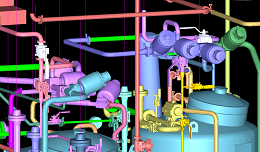

Design Process

Starting from PFD and P&ID, NeuMech Solutions provides the most cost effective concept design that meets process requirements. Moving forward, 3D design will be detailed and after approval all the documents and fabrication drawings will be prepared.

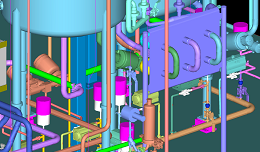

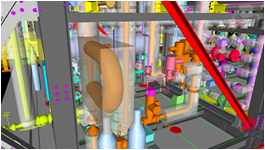

Piping Stress Considerations

Through concept and detail design, the operating and design temperature and pressure of critical lines are considered and having the experience of piping stress analysis, the piping is routed so that the changes after piping stress analysis will be minimized.

Operating Considerations

Maintenance and operating access is a key parameter while the piping systems are designed. This is consistently monitored during the design process and the feed backs from customer are applied to the design.

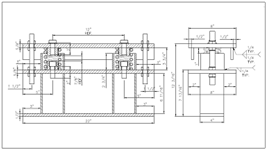

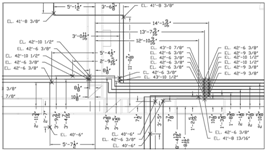

Documents and Drawings

ISO fabrication drawings and all other drawings and documentation such as piping layout, equipment GA, material take off, etc. are prepared according to customer request. Using macro programming and taking advantage of all the capabilities of CAD programs, the time of ISO and documents generations are minimized, providing all the necessary information for fabrication and installation on the prepared documentations.

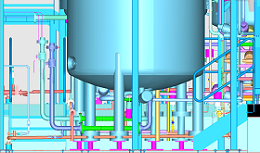

Modular Systems

Upon request the design can be performed for modular systems. If you are fabricating a modular system, NeuMech Solutions will provide the most compact equipment layout with minimum number of skids that meets your process requirements. This will lower the cost of piping and structural fabrication considerably.